Sustainability is one of the pillars of BPCL’s business and a main aspect of its organizational culture. Development at BPCL is based on the Triple Bottom Line model, meaning our continued commitment to the economic, social and environmental development of the communities we operate in. We are committed to: work towards the development of the society surrounding us, and strive to minimize our environmental footprint, improving conditions in surrounding areas, thus providing a better way of life for everyone.

At the core of our Sustainability strategy, we made a concerted effort to integrate the United Nation Sustainability Development Goals (UN SDGs) into our business decisions.

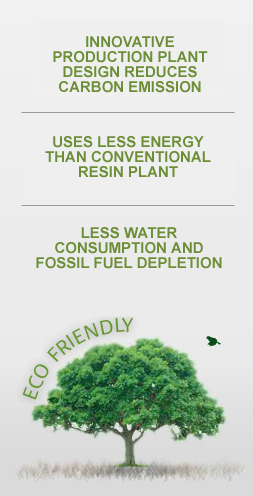

BPCL’s commitment to the environment drives the firm to establish actions and take measures that reduce its carbon footprints. The food-grade PET resin produced by BPCL requires 75% less energy than that used to produce virgin resin. BPCL is committed to the protection and improvement of the environment, and therefore comply with current laws and many other requirements that the organization subscribes to regarding ecological and environmental matters, including the rational and efficient use of resources.

Reducing carbon footprint:

Reducing water footprint:

Curbing generation of waste:

Waste Treatment Plant:

Packaging:

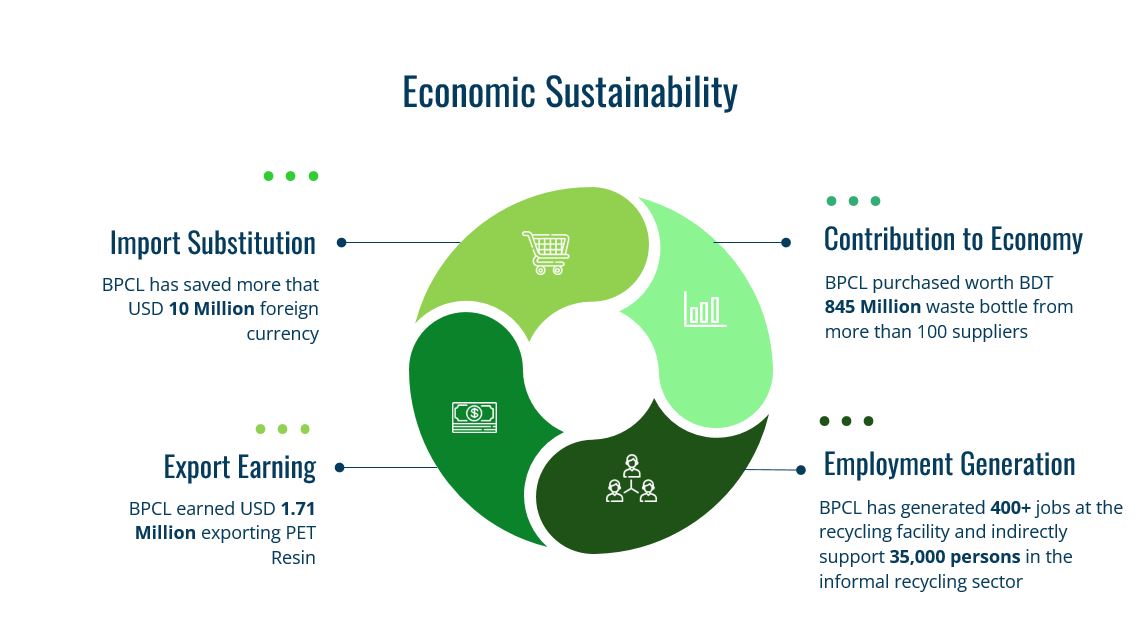

Our plant has ensured sustainable and resilient infrastructure to promote inclusive and self-bearing industrialization. With extensive scientific research and technological capabilities, we encourage innovation and raise Bangladesh's export and employment share.

BPCL

Our HQ is located in Dhaka, a global business hub.

Our locations

The Food and Drug Administration (FDA) was created to set standards for the safe production and storage of food, beverages and drugs, preparation equipment and packaging materials — including plastic.

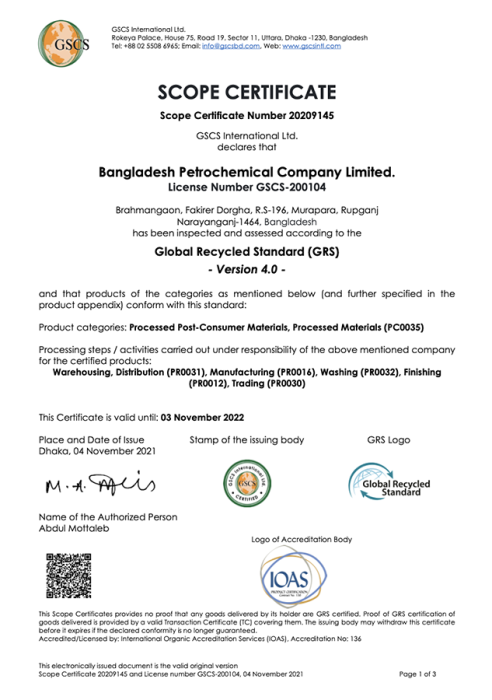

GRS Certification (Global Recycling Standard) is an international, voluntary, and comprehensive product standard that addresses supply chain manufacturers’ product recovery/regeneration components, regulatory chain controls, social responsibility and environmental regulations, and chemical restrictions.

The European Food Safety Authority is the keystone of European Union risk assessment regarding food and feed safety. EFSA provides independent scientific advice and clear communication on existing and emerging risks.

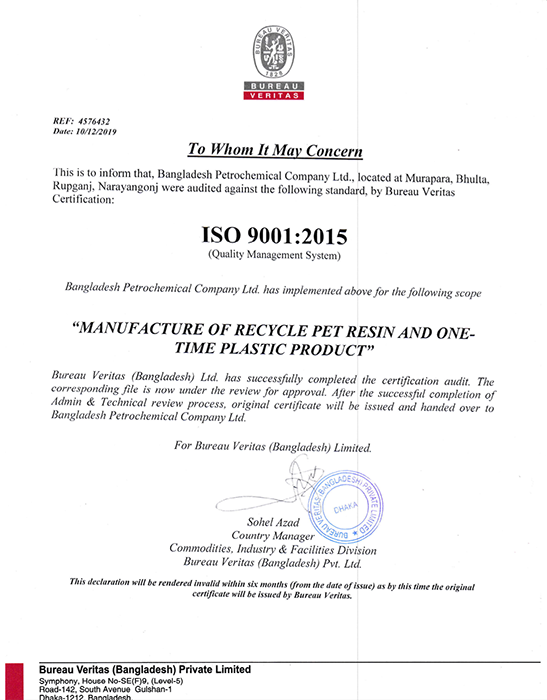

ISO 9001 is defined as the international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

Social Sustainability Plan

Scavengers in Bangladesh have low incomes, mainly because industry usually does not purchase recyclables directly from them because its minimum volume demands are beyond what most scavengers can provide and because the materials still need to be sorted, cleaned and baled, adding other labor costs for the purchaser. In the usual supply chains, middlemen obtain high profits by paying low prices to scavengers. Circumventing the middlemen is a goal for many organized scavengers. BPCL will intervene in the market to break this trend, purchase PET directly from scavengers, at a fixed price, in its hubs.